WMS SOFTWARE SOLUTION

ORDER FUNCTIONS

Find efficiency with a Warehouse Management System built to streamline and save time.

Prioritization

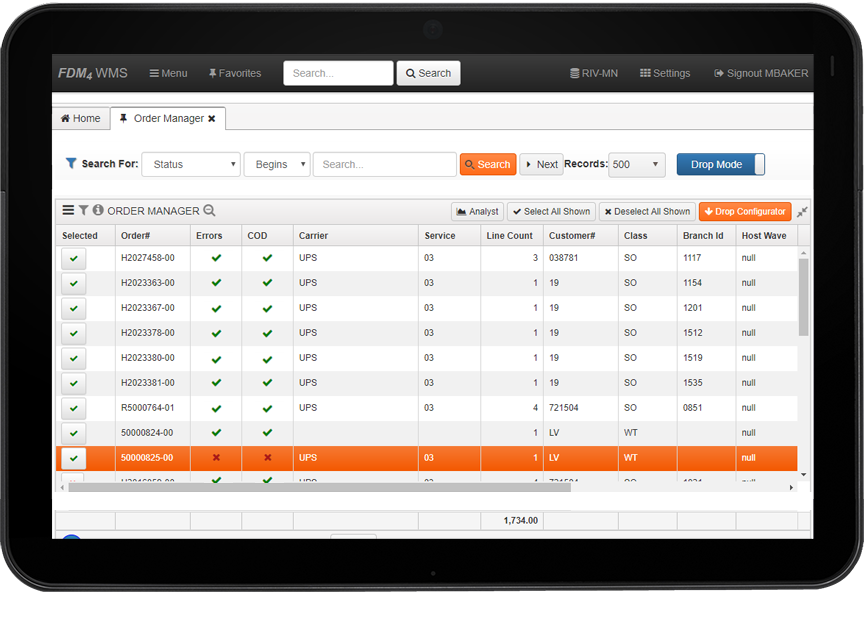

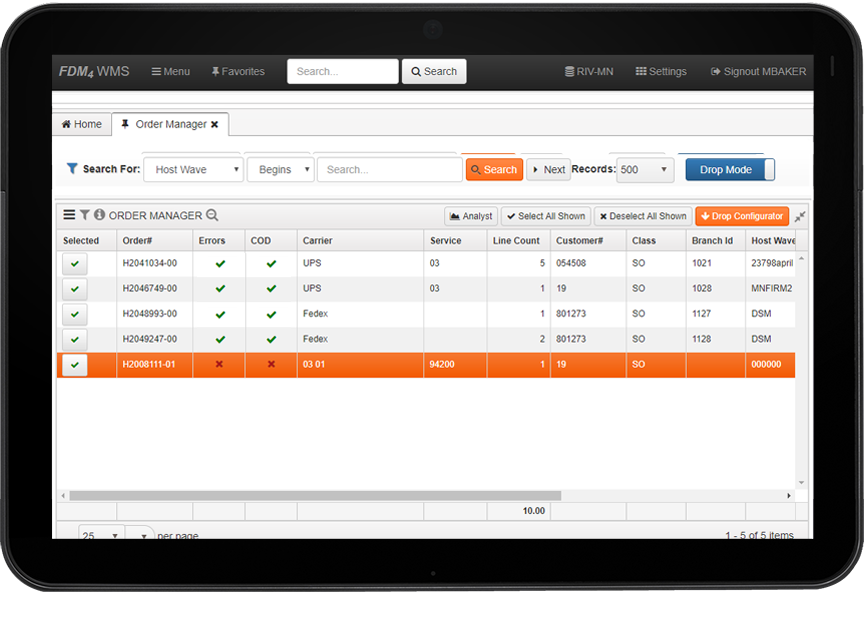

Order Management Screen is a flexible tool used to group and release orders for shipment. This easy-to-use, GUI screen gives the manager the capabilities of releasing Single orders or Groups of orders based on Order Number, Customer ID, Destination, Dates, Carriers, Priorities, and any combination thereof. At any point in the warehouse order process, an order can be immediately cancelled and FDM4 Warehouse Logistics will generate all the necessary tasks to re-stock the items already in the picking/shipping process.

Order Filtering

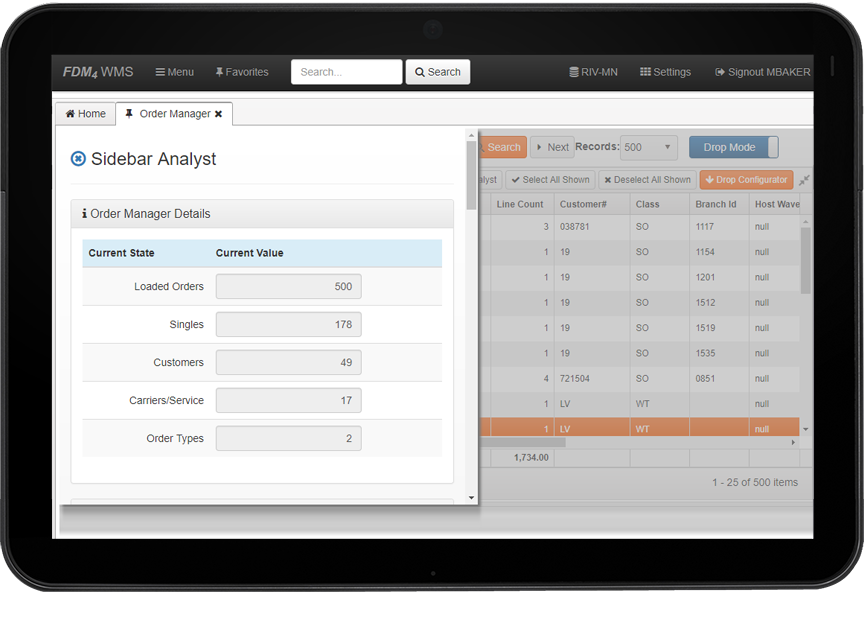

The FDM4 Order Manager is the desktop tool used by management to release work to the warehouse. The Order Manager gives an overview of the work available as provided by the host system. Totals by carrier, by customer, by wave, by expected shipment date and other categories are provided. The Order Manager releases work to the warehouse in waves through built in logic or a manual wave process. A wave consists of one or more orders. Each wave represents picking work to be done by warehouse employees. A wave is a collection of orders given to the warehouse as a unit. One or more warehouse personnel may pick a wave simultaneously.

Outbound Order Types

FDM4 can use its own logic to group orders into a wave, the warehouse manager can manually group orders into a wave, or the host system can group orders into a wave prior to sending those orders to FDM4. The FDM4Order Manager can accept and process several types of outbound orders: Customer Orders, Work Orders, Warehouse Transfers, and Counter Sales. Any order may consist of simple lines, i.e. order one product and pick one product, and/or kit lines. A kit line may be a pick-pack-and-ship kit or a build-on-demand kit.

Work Assignment

A build-on-demand kit is defined to FDM4 as assembly required. For assembly-required kits, the raw materials needed are moved via RF to the appropriate Work Center where production of a finished good is recorded. When, within the Work Center, the finished good has been produced and its raw materials consumed, an RF pick is generated for the finished good in the Work Center’s picking stage-out area. Work orders are a special type of order received from the host system. The intent of work orders is to direct a Work Center to use raw materials to produce finished goods, which are then put away for later picking by customer orders or warehouse transfers.